Choosing the Right Welding Tools For Your Next Project

Introduction to Welding Tools and Their Importance

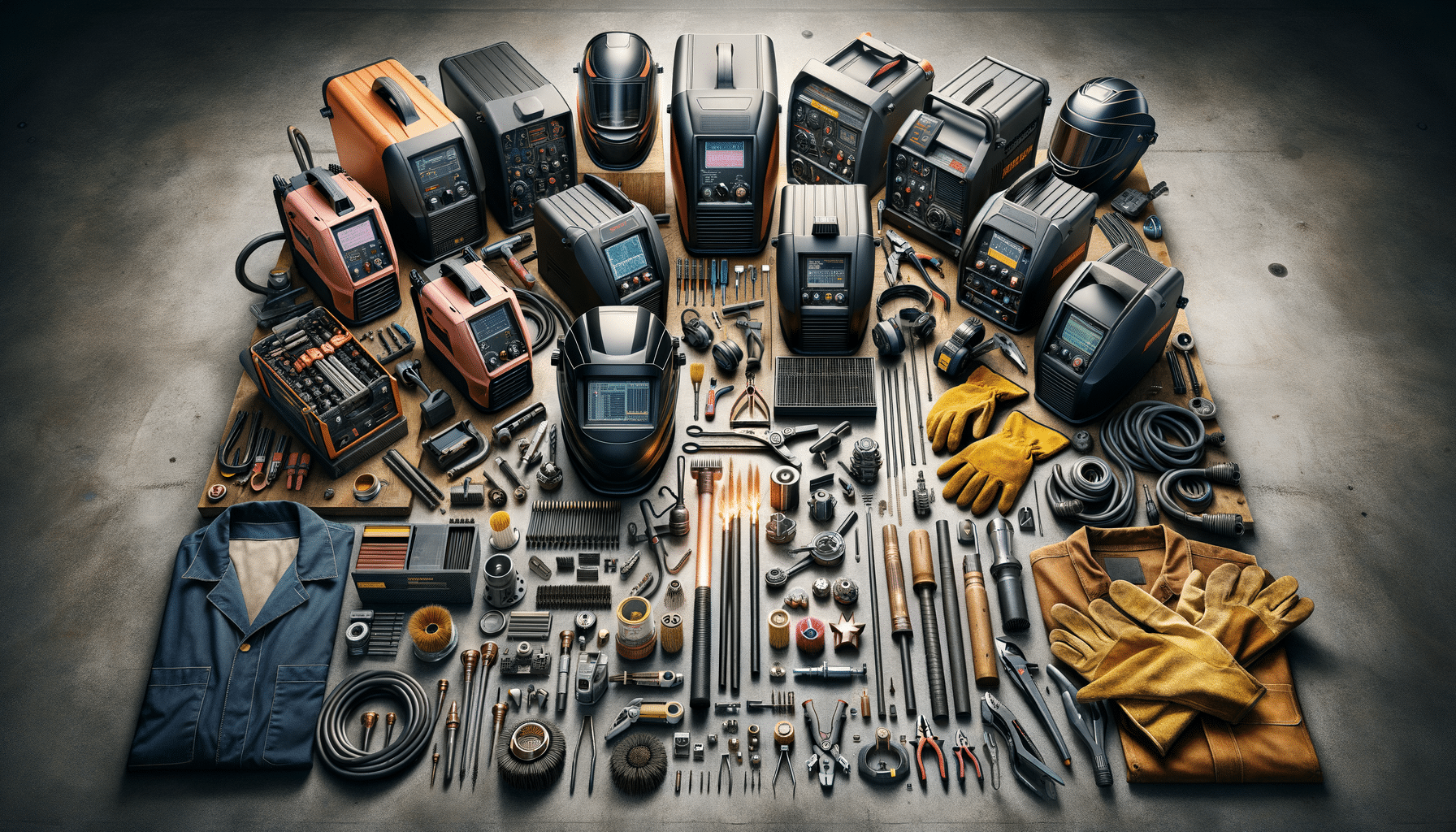

Welding is a fundamental skill in various industries, from construction to automotive manufacturing. The right welding tools not only enhance efficiency but also ensure safety and precision in your work. Whether you’re a professional welder or a DIY enthusiast, understanding the different types of welding tools and equipment is crucial. This guide aims to provide a comprehensive overview of the essential tools and supplies needed for successful welding projects.

Essential Welding Tools

Welding requires a range of tools, each serving a specific purpose. Among the most crucial are welding machines, which come in various types such as MIG, TIG, and stick welders. Each type is suited for different materials and project requirements. For instance, MIG welders are often chosen for their ease of use and versatility, making them ideal for beginners.

In addition to the welding machine, other tools are indispensable for a welder’s toolkit. These include:

- Welding Helmet: Protects the eyes and face from sparks and harmful UV rays.

- Gloves: Essential for hand protection against heat and metal spatter.

- Clamps: Hold metal pieces in place during welding.

- Chipping Hammer: Used to remove slag from welds.

- Wire Brush: Cleans the surface before and after welding.

Investing in high-quality tools can significantly impact the quality of your welds and your overall welding experience.

Welding Equipment and Supplies

Beyond the basic tools, welding equipment encompasses a variety of accessories and consumables that are vital for efficient operation. For instance, welding rods or electrodes are essential supplies that vary depending on the material being welded. Similarly, shielding gas is crucial for processes like MIG and TIG welding to protect the weld area from atmospheric contamination.

Another important aspect of welding supplies is safety equipment. This includes fire-resistant clothing, safety glasses, and ear protection. Ensuring you have the right protective gear is paramount to prevent injuries and accidents in the workshop.

Furthermore, maintaining a well-organized workspace with adequate ventilation and proper lighting can enhance safety and efficiency. Regular maintenance of welding equipment, such as checking for leaks in gas hoses and ensuring electrical connections are secure, is also essential for optimal performance.

Conclusion: Making Informed Choices

Choosing the right welding tools and equipment is a critical step in achieving successful welding outcomes. By understanding the specific needs of your project and investing in quality tools and supplies, you can enhance both the safety and quality of your work. Whether you’re tackling a small DIY project or a large industrial task, being well-equipped will lead to better results and a more enjoyable welding experience.

As you venture into your next welding project, remember that the right tools are not just about convenience—they’re about ensuring precision, safety, and efficiency. Equip yourself with knowledge and the best tools for your needs, and you’ll be well on your way to mastering the art of welding.